Why Are Metal Foil Resistors the Preferred Choice in High-Frequency Circuits

2025-12-18

When designing high-frequency circuits for RF applications, precision test equipment, or advanced telecommunications, the choice of Resistor Components is critical. Standard resistors often suffer from parasitic inductance and capacitance at high frequencies, leading to signal integrity loss and measurement errors. This is where Greeting Electronics' advanced Metal Foil Resistors excel, offering unmatched stability and accuracy where it matters most. Our Greeting FHR Series is engineered specifically to meet the rigorous demands of high-speed and high-frequency environments.

The superiority of Greeting's metal foil technology lies in its precise parameter control. The resistive element is a thin bulk metal foil bonded to a ceramic substrate, minimizing parasitic effects and providing exceptional performance.

Key Advantages of Greeting FHR Series Resistors:

-

Extremely Low Parasitic Inductance (<0.08 µH): Ensures minimal impedance change at high frequencies.

-

Ultra-Low Noise & Excellent Thermal Stability: Provides a stable signal and reliable operation under thermal stress.

-

Tight Tolerance & Near-Zero TCR: Available with tolerances down to ±0.01% and Temperature Coefficient of Resistance (TCR) as low as ±2 ppm/°C.

-

Fast Thermal Stabilization: Responds quickly to temperature changes, preventing drift during operation.

For a quick technical comparison, see the table below highlighting our flagship model's specifications:

| Parameter | Greeting FHR-0402 Specification | Benefit for HF Circuits |

|---|---|---|

| Resistance Range | 1 Ω to 50 kΩ | Wide applicability for various circuit functions. |

| Tolerance | ±0.01% to ±0.1% | Ensures precise voltage division and current sensing. |

| TCR (ppm/°C) | ±2, ±5 | Maintains accuracy across a wide temperature range. |

| Parasitic Inductance | < 0.08 µH | Preserves signal integrity in RF and fast-switching apps. |

| Power Rating | 250 mW @ 70°C | Reliable power handling in compact designs. |

Resistor Components FAQ

Q: What is the main difference between metal foil and thin film resistors in high-frequency use?

A: While both are precision components, metal foil resistors from Greeting have a bulk metal element, yielding inherently lower parasitic inductance and better TCR. Thin film resistors, with their deposited metal layer, can exhibit higher parasitic effects at very high frequencies, making foil types superior for critical RF and measurement applications.

Q: How does low parasitic inductance in a resistor benefit my circuit board design?

A: Low parasitic inductance, a hallmark of our Greeting foil resistors, prevents the component from behaving like an unwanted inductor at high frequencies. This minimizes phase shift, reduces ringing in pulse circuits, and ensures the resistor's impedance stays close to its stated DC value, crucial for maintaining signal fidelity and measurement accuracy.

Q: Are these high-performance Resistor Components suitable for power-sensitive applications?

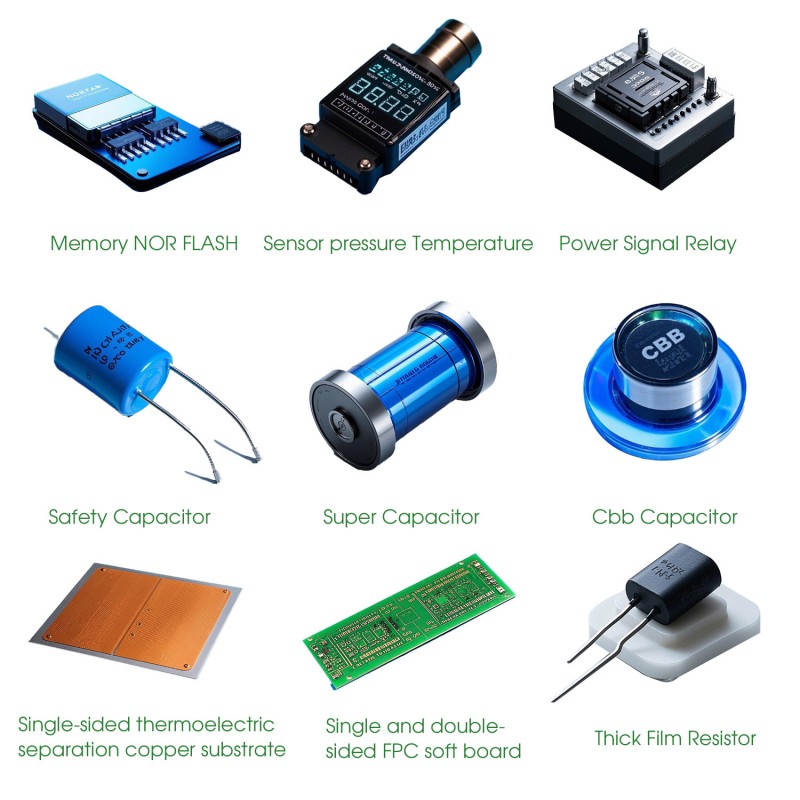

A: Greeting metal foil resistors are optimized for precision, not power dissipation. They are ideal for signal conditioning, sensing, and instrumentation where accuracy and stability are paramount. For high-power applications, other Resistor Components like our wirewound or thick film power resistors would be more appropriate.

To unlock the full potential of your high-frequency designs with components that guarantee precision and reliability, partner with Greeting Electronics. Our engineering team is ready to support your specific application challenges. Contact us today to request samples, detailed datasheets, or a technical consultation for your next-generation projects.