What Is the Role of High Frequency Boards in 5G Communication Systems

2025-12-04

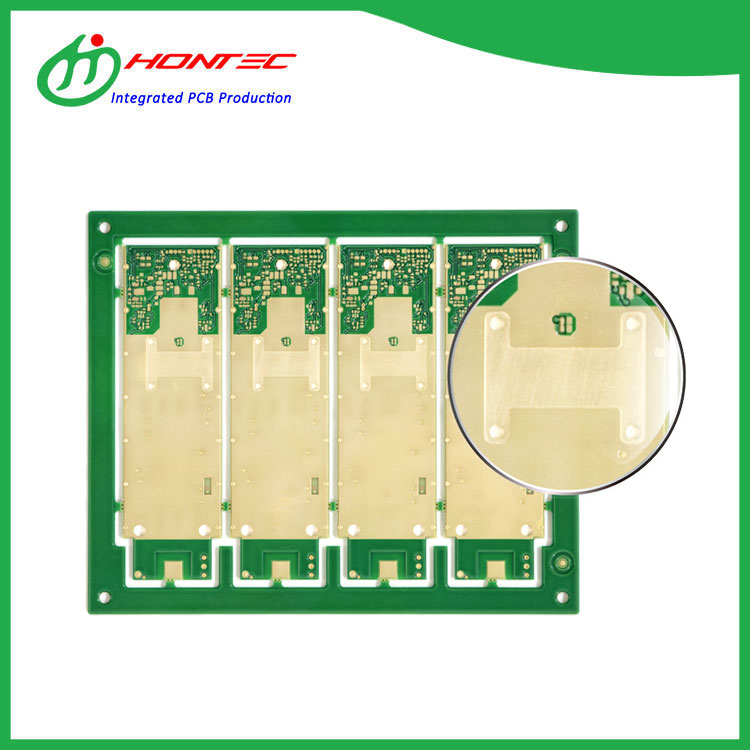

The advent of 5G technology has revolutionized connectivity, demanding unprecedented speed, bandwidth, and low latency. At the heart of this transformation lies a critical, yet often unseen component: the High Frequency Board. These specialized PCBs are engineered to handle signals in the GHz range with minimal loss, making them indispensable for 5G infrastructure. At HONTEC, we design and manufacture premium High Frequency Boards that form the reliable backbone of next-generation communication, from massive MIMO antennas to core network equipment.

Unlike standard PCBs, High Frequency Boards for 5G require exceptional electrical properties. HONTEC's products are defined by precise parameters that ensure optimal performance in demanding 5G environments.

Key Product Parameters at HONTEC:

-

Low Dielectric Constant (Dk): Ranging from 2.2 to 3.5, providing stable signal propagation speed.

-

Ultra-Low Dissipation Factor (Df): As low as 0.0017 at 10 GHz, minimizing signal energy loss and heat generation.

-

Superior Thermal Conductivity: Up to 1.5 W/m/K, ensuring effective heat dissipation from high-power RF components.

-

Controlled Impedance: Tight tolerances of ±5% or better for consistent signal integrity.

| Material Type | Typical Dk @ 10 GHz | Key Application in 5G |

|---|---|---|

| Rogers RO4000 Series | 3.38 - 3.66 | Antenna feeders, power amplifiers |

| Taconic TLY Series | 2.20 - 2.33 | Low-loss phased array antennas |

| HONTEC Custom Hybrid | 2.5 - 3.2 (Configurable) | Integrated Radio Units (RUs) |

High Frequency Board FAQ

Q: Why can't standard FR-4 boards be used for most 5G applications?

A: Standard FR-4 has a high and inconsistent Df, leading to significant signal attenuation and distortion at high frequencies. HONTEC’s specialized materials maintain signal clarity and strength essential for 5G's high-data-rate transmission.

Q: How does impedance control on a High Frequency Board impact 5G performance?

A: Precise impedance control prevents signal reflections at junctions. Any mismatch in a 5G system causes data errors and reduces spectral efficiency. HONTEC employs advanced modeling and manufacturing processes to guarantee impedance accuracy across the entire board.

Q: What are the major challenges in manufacturing High Frequency Boards for 5G?

A: The primary challenges involve material handling (as many high-frequency laminates are brittle), achieving fine-line etching for complex circuits, and ensuring perfect plating for low-surface roughness—all of which are critical to minimize insertion loss. HONTEC’s expertise lies in mastering these precise manufacturing techniques to deliver reliable, high-yield boards.

Empower Your 5G Innovations with HONTEC

The reliability of your 5G system is directly linked to the quality of its foundational High Frequency Boards. Choosing a partner with deep material knowledge and precision manufacturing is crucial. HONTEC provides not just components, but solutions engineered for the future of connectivity. Let us help you build faster, more reliable, and efficient 5G systems.

Ready to integrate superior High Frequency Board technology into your next 5G project? Contact us today for a detailed consultation and quote. Our engineering team is here to support your most advanced design challenges.