How to Troubleshoot a Malfunctioning Ceramic Ozone Plate in a Generator

2025-12-08

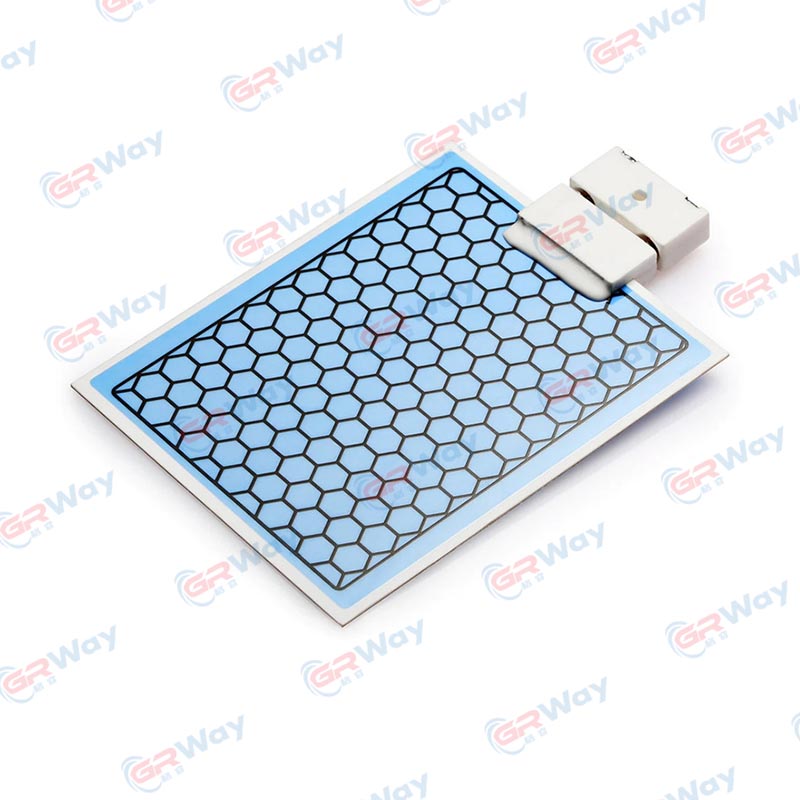

A malfunctioning ozone generator can disrupt critical processes in water treatment, air purification, or industrial applications. Often, the core component—the Ceramic Ozone Plate—is at the heart of the issue. As a leader in advanced oxidation technology, GREENWAY is committed to ensuring your system operates at peak efficiency. This guide will help you systematically troubleshoot a Ceramic Ozone Plate and identify common problems, helping you restore your GREENWAY generator's performance.

Step-by-Step Troubleshooting Guide

-

Safety First: Always disconnect power and allow the generator to cool completely before inspection. Ensure the area is well-ventilated.

-

Visual Inspection: Carefully remove the Ceramic Ozone Plate. Look for:

-

Cracks or Chips: Physical damage is a primary failure reason.

-

White Mineral Deposits: Indicates hard water or humidity issues.

-

Discoloration or Corrosion: May point to gas contamination or electrical problems.

-

-

Check Electrical Connections: Ensure all high-voltage connections to the plate are secure and free from carbon tracking or arcing marks.

-

Test the Environment: Use an ozone meter to check if the unit is producing any ozone. No output suggests plate or power supply failure.

-

Evaluate Supporting Systems: Verify the oxygen source (dry air or oxygen feed) is clean, dry, and at the correct flow rate. Contaminants drastically reduce plate life and efficiency.

To understand if your plate is performing to specification, refer to the typical parameters for a GREENWAY standard industrial plate:

| Parameter | Specification | Importance |

|---|---|---|

| Ozone Output | 5-10 g/h (model dependent) | Measures plate productivity. |

| Operating Voltage | 4-6 kV | Critical for correct dielectric discharge. |

| Plate Thickness | 1.0 ± 0.1 mm | Affects durability and discharge efficiency. |

| Dielectric Constant | > 9 | Key for effective ozone generation. |

| Expected Lifespan | 10,000 - 15,000 hours | With proper operating conditions. |

Ceramic Ozone Plates FAQ

Q: What is the most common reason for a premature failure of a Ceramic Ozone Plate?

A: The most common cause is exposure to moisture or humidity in the feed gas. Water vapor causes arcing, hotspots, and mineral deposition, which physically erode and crack the ceramic dielectric layer. Using a properly sized air dryer is essential.

Q: Can I clean a dirty GREENWAY Ceramic Ozone Plate?

A: Light surface deposits can sometimes be gently cleaned with a soft brush and isopropyl alcohol after the plate is fully disconnected and dry. However, deep mineral scaling or micro-cracks often necessitate replacement, as cleaning cannot restore the compromised dielectric layer.

Q: How do I know if the problem is the plate or the generator's power supply?

A: A professional method is to substitute the suspect plate with a known-working unit. If the new plate produces ozone normally, the original plate is faulty. If the problem persists, the high-voltage power supply, transformer, or control circuit likely requires service.

Persistent issues with ozone output often point to a degraded Ceramic Ozone Plate that needs replacement. Don't let downtime affect your operations. GREENWAY manufactures reliable, high-performance Ceramic Ozone Plates engineered for longevity and consistent output.

Contact us today for expert technical support, to order genuine replacement plates, or to discuss optimizing your entire ozone system with GREENWAY components.